| brand | Kehai | Yes / No support for processing | yes | Specifications | 4500mm |

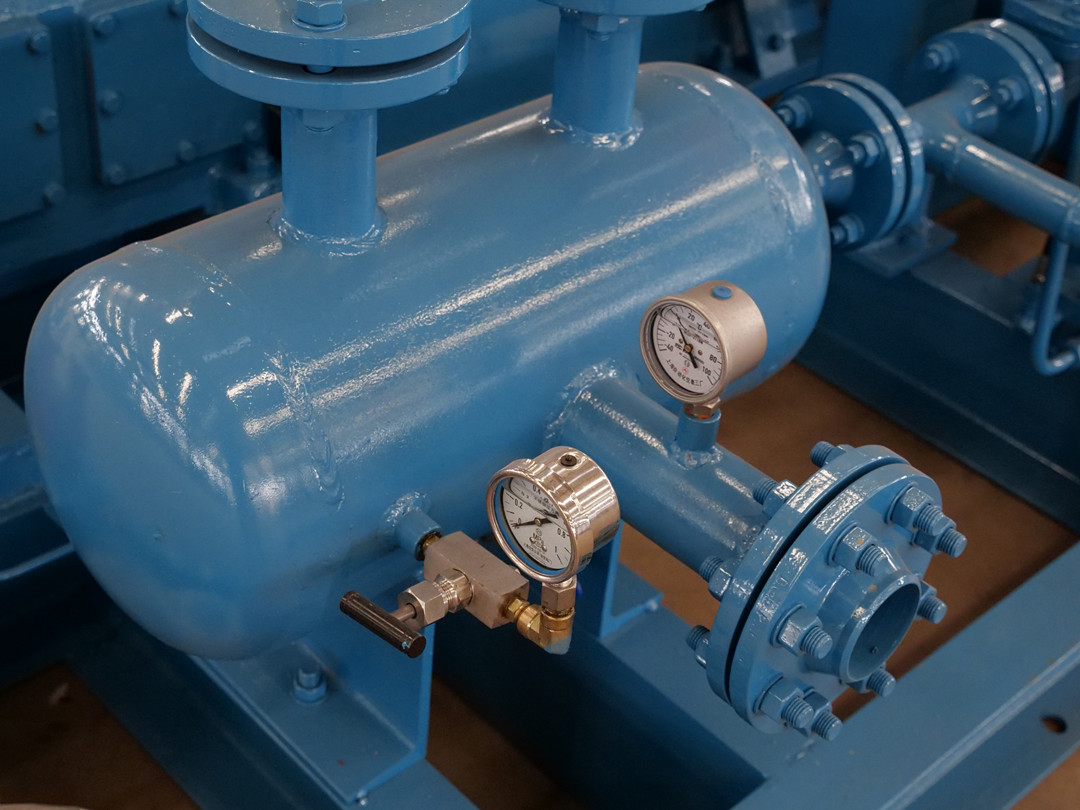

| Compressed medium | Natural Gas | admission pressure | 0.2-0.4MPa | Discharge pressure | 0.6MPa |

| rate of flow | 2.6cubic / min | temperature | 40 | Cooling-down method | air cooling |

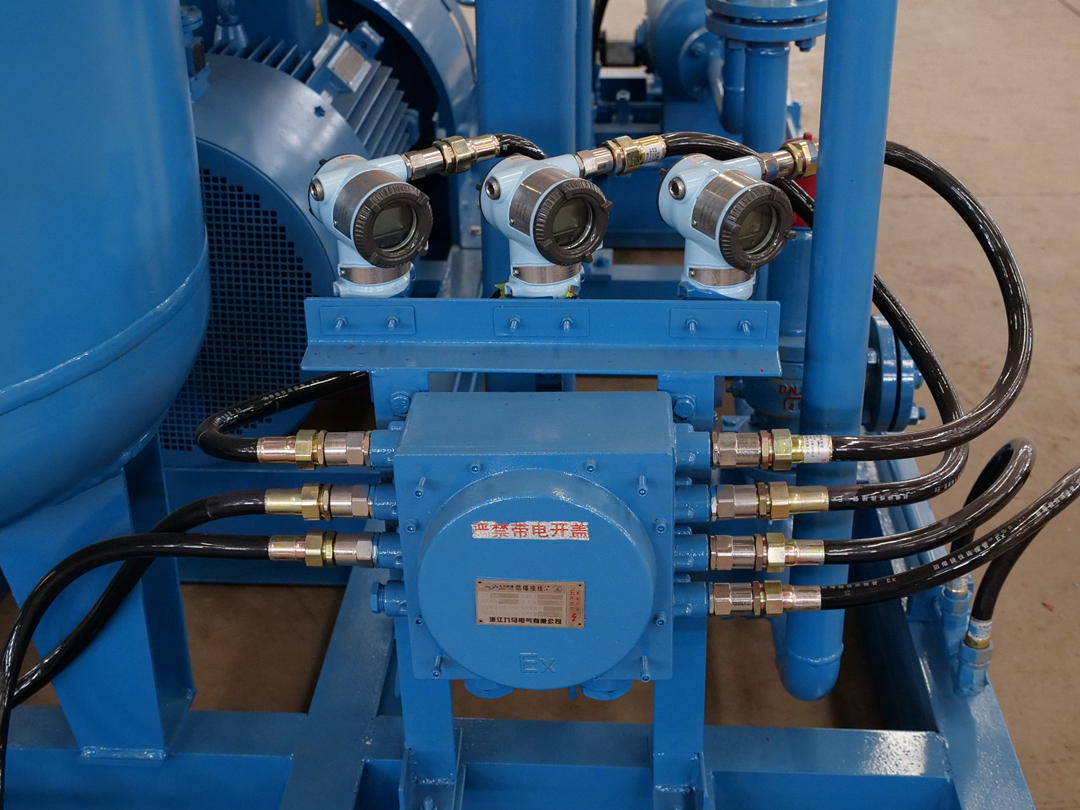

| navar | PLC | dimensions | 4500*2200*1400mm | lubricating system | forced lubricgtion |

| power of motor | 220KW | Available for sale | globally | Model | ZW-2.6/(2-4)-6 |

Kehai

ZW507 Vertical Ammonia LPG Unloading Compressor for Booster Station Golbal Supply

Customize products according to user’s working conditions parameters.

The working medium of the LPG circulating compressor is civil LPG or similar gas, such as ammonia. It is mainly used for the pressurization of liquefied petroleum gas (LPG) or gas with similar properties, and it can also be used for vacuuming. Therefore, this type of compressor is the key equipment of cities, factories, mines, terminals, liquefied petroleum gas storage and transportation stations, liquefied petroleum gas bottling plants, liquefied petroleum gas automobile filling stations, and it is also the ideal equipment for chemical enterprises to pressurize and recover gas. It can implement the following work:

1. Loading and unloading of liquefied petroleum gas tank truck and tank ship;

2. liquefied petroleum gas station or bottling, backfilling with similar nature;

3. Pressurization of liquefied petroleum gas mixing station;

4. Recovery of liquefied petroleum gas and liquid residues;

Minimum order quantity:

1 pieces.

Inquire Nowproduct description

Tags:

buy liquefied gas compressor China Liquefied gas compressor Liquefied gas compressor factory Liquefied gas compressor price Liquefied petroleum gas compressor LPG compressor For LPG Gas Station LPG Unloading Compressor for Booster Station LPG Unloading Compressor Golbal Supply Vertical Ammonia LPG Unloading Compressor ZW507 liquefied gas compressor plantService Process

-

01

Project communication

-

02

Exchange of technical parameters

-

03

Develop a design plan

-

04

Sign a contract

-

05

Compressor manufacturing

-

06

Packaging and transportation

-

07

Installation, operation and debugging

-

08

Customer training

-

09

Customer acceptance