As the hydrogen energy industry continues to expand across fuel cells, hydrogen refueling stations, chemical processing, and green hydrogen production, the demand for safe, oil-free, and high-purity hydrogen compression solutions is growing rapidly. Among various hydrogen compressor technologies, the ضاغط هيدروجين غشائي stands out as one of the most reliable and contamination-free options for high-pressure hydrogen applications.

This article explains what a diaphragm hydrogen compressor is, how it works, its advantages, key applications, and how to choose the right model for your hydrogen system.

What Is a Diaphragm Hydrogen Compressor?

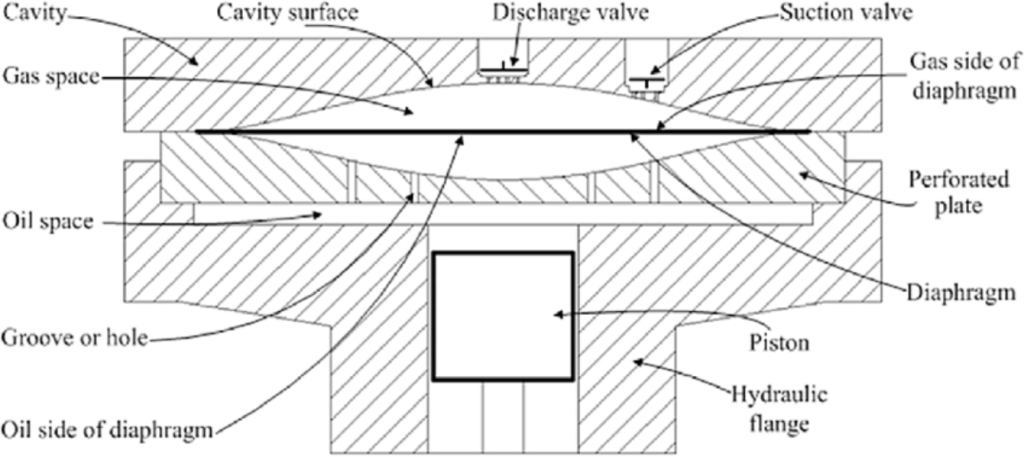

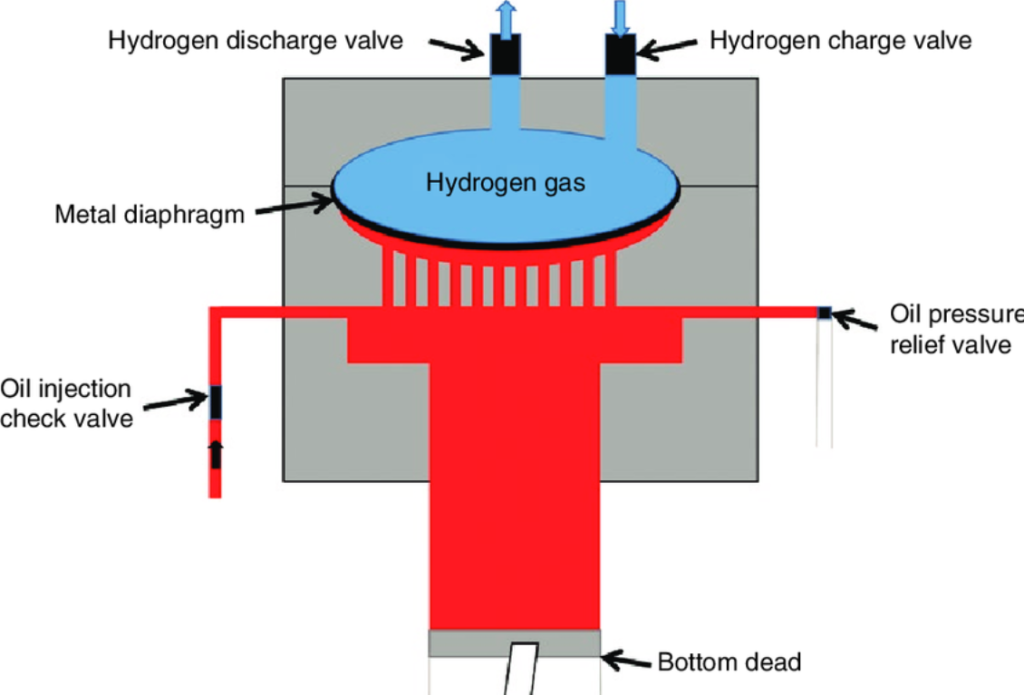

A ضاغط هيدروجين غشائي is a type of positive displacement compressor that uses a flexible metal diaphragm to compress hydrogen gas instead of traditional pistons or oil-lubricated cylinders. The gas chamber is completely sealed from the hydraulic drive system, ensuring zero oil contamination and extremely high gas purity.

This design makes diaphragm compressors ideal for applications that require high-pressure hydrogen compression, leak-free operation, and maximum safety, such as hydrogen refueling stations, electrolyzer systems, laboratory research, and hydrogen storage systems.

How Does a Diaphragm Hydrogen Compressor Work?

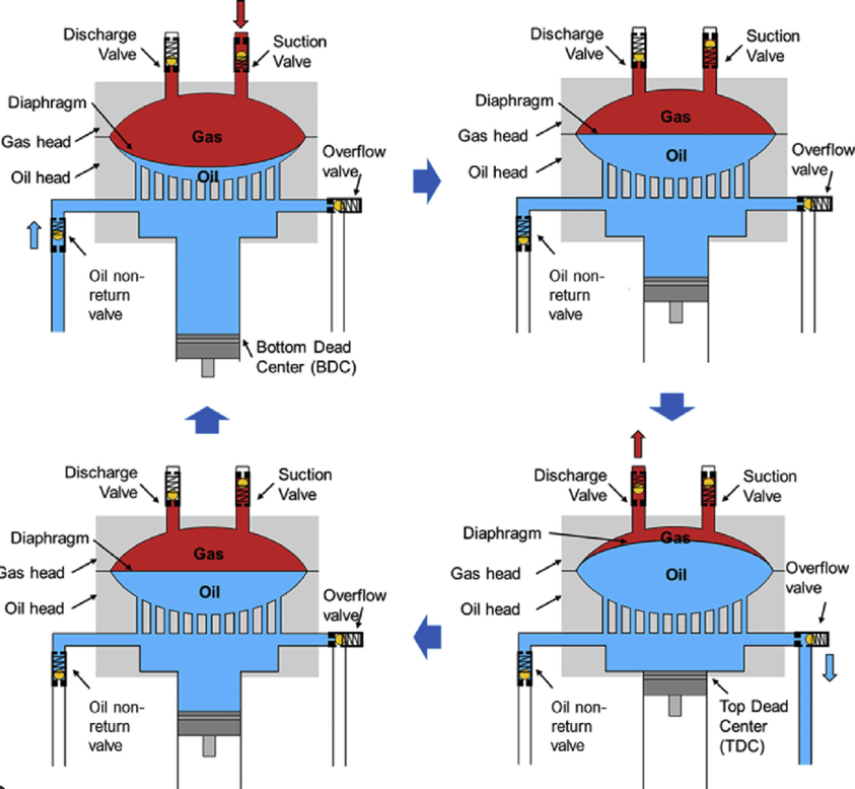

A diaphragm hydrogen compressor operates using a hydraulically driven diaphragm that moves back and forth to compress hydrogen gas in a sealed chamber. The process typically follows these steps:

- Gas Intake

Hydrogen enters the compression chamber through an inlet valve during the suction stroke. - Compression Phase

Hydraulic oil pushes the diaphragm forward, reducing the chamber volume and increasing gas pressure. - Discharge Phase

Once the target pressure is reached, hydrogen exits through the discharge valve into downstream storage cylinders, pipelines, or tanks. - Cycle Repeat

The diaphragm returns to its original position, allowing the next compression cycle to begin.

Because the hydrogen gas never contacts oil, seals, or moving mechanical parts, diaphragm compressors offer superior purity control, leak prevention, and operational safety.

Key Advantages of Diaphragm Hydrogen Compressors

1. Oil-Free and Ultra-High Purity

The sealed diaphragm chamber prevents oil vapor, moisture, and particulate contamination, making these compressors ideal for fuel cell-grade hydrogen and laboratory use.

2. Excellent Leak Tightness and Safety

Diaphragm compressors provide near-zero leakage rates, which is critical when handling flammable hydrogen gas and meeting strict safety standards.

3. High Pressure Capability

Modern diaphragm hydrogen compressors routinely achieve discharge pressures of 350 bar, 700 bar, and beyond, suitable for hydrogen refueling stations and high-pressure storage systems.

4. Long Service Life and Low Maintenance

Metal diaphragms are engineered for millions of cycles, and because gas-side components experience minimal wear, maintenance intervals are longer than many piston compressors.

5. Stable Performance at Small to Medium Flow Rates

They offer precise pressure control and stable flow, making them ideal for continuous-duty hydrogen systems.

Typical Applications of Diaphragm Hydrogen Compressors

Diaphragm hydrogen compressors are widely used in:

- Hydrogen refueling stations (HRS) for FCV fueling systems

- Electrolyzer outlets in green hydrogen production plants

- Fuel cell testing and laboratories requiring ultra-high-purity hydrogen

- Hydrogen storage systems, including cylinder filling and tube trailers

- Chemical processing and semiconductor manufacturing

These applications benefit from the compressor’s oil-free design, tight sealing performance, and reliable high-pressure operation.

Diaphragm vs. Piston Hydrogen Compressors

| ميزة | ضاغط هيدروجين غشائي | Piston Hydrogen Compressor |

|---|---|---|

| Gas purity | Ultra-high (oil-free) | Risk of oil carryover |

| Leak rate | Extremely low | Moderate |

| أمان | Very high | Standard |

| Pressure capability | Very high (up to 700 bar+) | Medium to high |

| صيانة | Low | Higher |

| Best for | High-purity, high-pressure hydrogen | Large flow industrial gas |

For applications requiring high hydrogen purity, safety, and leak-free performance, diaphragm compressors are generally the preferred solution.

How to Choose the Right Diaphragm Hydrogen Compressor

When selecting a diaphragm hydrogen compressor, consider the following parameters:

- Inlet and outlet pressure range (e.g., 30 bar to 350 bar or 700 bar)

- Flow rate requirements (Nm³/h or kg/h)

- Hydrogen purity specifications

- Duty cycle and operating hours

- Cooling method (air-cooled or water-cooled)

- Compliance standards (ISO, CE, ASME, ATEX, etc.)

Working with an experienced manufacturer ensures proper sizing, system integration, and long-term operational reliability.

Why Choose Our Diaphragm Hydrogen Compressors?

At كيهاي, we specialize in custom-engineered diaphragm hydrogen compressors designed for hydrogen refueling stations, electrolyzer systems, laboratories, and industrial hydrogen storage. Our compressors feature:

- Oil-free, contamination-free compression chambers

- High-pressure designs up to 700 bar and beyond

- Robust multi-layer metal diaphragms for extended service life

- Low vibration, quiet operation, and high energy efficiency

- Full compliance with international hydrogen safety standards

Whether you need a compact laboratory hydrogen compressor or a heavy-duty industrial hydrogen compression system, our engineering team can deliver reliable, safe, and cost-effective solutions tailored to your project.

Contact us today to get a customized diaphragm hydrogen compressor solution for your hydrogen application.